Belgian Dubbel

In lieu of specialty grains, send candi sugar.

Not to toot my own horn (which I'm about to do anyways), but I've had a pretty strong run in some inter-club homebrew competitions recently. Out of the last 3 competitions, I won two and took 3rd in another. Sadly a computer crash wiped all traces of one of the recipes (rye saison finished with brett) and all the pics of a 2nd (Vienna Lager, slight recipe re-formulation will make it onto the blog later this year), but you can see the Kolsch that took 3rd.

What does all this have to do with a Belgian Dubbel? Well, it was May 2017's style for the competition and since I brewed it back in October, I figure I should probably get around to writing it up. There are a few roads to take you to Dubbel City. You can go grain only with no candi sugar using just base and specialty malts; base malt with candi sugar/syrup for color and flavor; or a combo of base and specialty malts with sugar. For this beer, I did something I've never done before, I brewed a clone recipe from a website. Or to be more precise, I copied the grain bill exactly but used different hops and a different yeast that I particularly love. So maybe I didn't really brew a clone recipe. The grain bill was based off the Westvleteren 8 clone from the wonderful Candi Syrup, Inc website.

Hmmm, I don't think that'll get the necessary SRM and flavors I need.

Belgian Dubbel Clone, batch size 11 gallons:

Grains

- 18 lbs Belgian Pilsner

- 5 lbs Belgian Pale Malt

- 3 pounds D-180 Candi Syrup

- 1.5 pounds Brun Fonce Cassonade Sugar

Mash at 149 for 60 minutes. Bring temp up to 162F by adding boiling water and let rest for 10 minute, then add more boiling water to get up to 170 and let sit for 15 minutes before draining and sparging. I also added 11g gypsum and 5.5g CaCl2 to the mash water and added lactic acid to get to a mash pH of 5.4.

Boil additions (90 minute boil):

- 0.4 oz Magnum @ 90 min (total of 10 IBUs)

- 2 oz Hallertauer Mittelfrueh @ 30 minutes

- 2 oz of Fuggles @ 10 minutes

- Added all sugar @ 10 minutes

Fermentation Plan:

- White Labs Belgian Saison III (WLP585) for yeast. This yeast gives a very subtle hint of clove and phenol spice while kicking out great fruity esters (it was the main yeast I used in my winning rye saison recipe, along with WLP670 Farmhouse blend).

- I started fermentation at 65F and upped the temperature 2 degrees every day for 10 days until it hit 85F, where it was held for a week before gravity check, cold crashing, and kegging.

Living dangerously here!

The brew day went well as always, crushed the grain, ended up a degree high on the 149F rest, a degree low on the 162F rest, spot on at 170F. The boil was a bit tricky, I over sparged a bit which meant I was dangerously close to boiling over for the first 30 minutes. Luckily disaster was avoided, though the extra sparging meant my efficiency was a touch higher than normal and when all was said and done, my OG was a higher than expected. I added the sugars near the end of the boil (with the 10 minute hop addition), chilled and filled up my carboys.

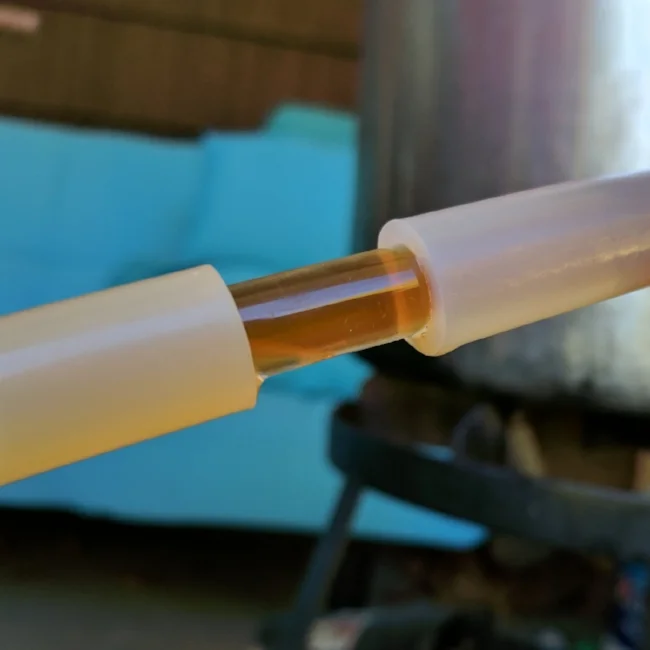

This is how I aerate my chilled wort. Poke a tiny hole in a short little tube and let physics do its thing.

Once in carboys and cooled to 65F, I added the WLP585 yeast and every day increased the temperature by 2F until it hit 85F. I like to start Belgians a bit lower, so the first few days of fermentation don't get out of hand with phenol/ester production. By the time it gets up into the mid 70s, most of the fermentation is done, so the yeast character that develops doesn't have any fusel alcohols or bubblegum esters that you can get if the fermentation gets too hot those first few days. After cold crashing and kegging, I burst carbbed the beers overnight at 35PSI, and let them sit in my kegerator for 1 week at 12PSI. At this point I drew off a pint to clear any sediment from the kegs, and took one of them out of my kegerator to condition in my basement over the winter/spring (at ~65F). The other keg stayed in the kegerator during that time at ~40F. I did this to see if there was a detectable difference between the beers after a 5 month aging difference.

After I put both back on tap 5 months later, I noticed a some interesting differences. The beer that stayed in the kegerator has less alcohol warmth to it, even as it gets up to room temp, but the fruitiness is more subdued. Whereas the cellar aged beer has a much more pronounced fruitiness to it with a little more warmth to it that brings out the phenols a bit more. I think I prefer the cellar aged version, but both are beautiful beers with a deep copper hue when the sun hits them.

I have since upgraded to a stainless steel siphion with a carboy cap so I don't have to hold this anymore.

While the recipe is fantastic and I'm enjoying the hell out of it, I would definitely change the following: get rid of the Brun Fonce sugar completely and use 2 pounds of D-180 along with 1 pound of Golden Candi Syrup while keeping everything else the same. It'd lighten the color up (it's a bit dark for style), cut down on the fruitiness of the beer a bit (again bringing more into style), and it would drop the ABV by a bit over 1%. While the beer doesn't taste boozy, it drinks way smoother than 8.8% and gets you buzzed pretty good pretty quickly (is that really a complaint).

And (toot toot) it took 2nd in the club competition. Not bad Belgian Dubbel, not bad at all.

Look at that deep copper glow.

Final numbers for my Belgian Dubbel:

- Batch Size: 11 gallons

- Original Gravity: 1.075

- Final Gravity: 1.008

- ABV: 8.8%

- IBU: 22